Medical Silicone Cable pricing

Medical Silicone Cable pricing

Without considering the quantity,the silicone cable price is decided by 3 main factors

Factor 1

Materials cost

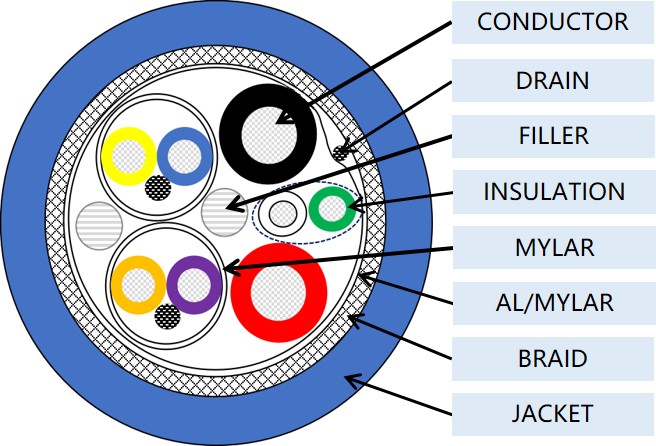

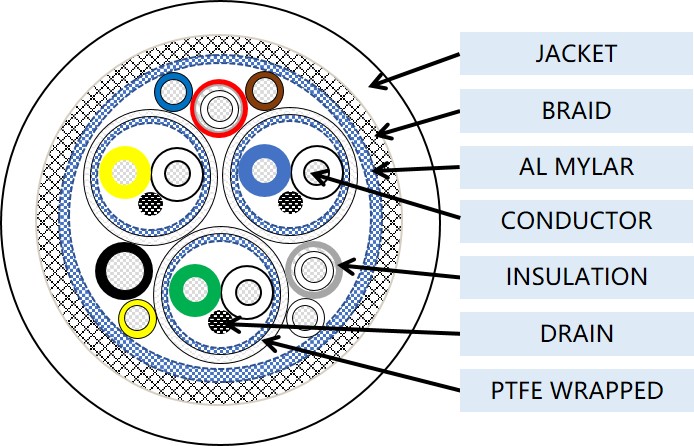

Silicone cable materials can be devided into:

Conductor material cost:Bare Copper,Tinned Copper,Silver plated Copper,and Alloy based on the previous items.

Insulations:the main insulations for silicone cable are:Teflon(ETFE,FEP,PFA,TPFE) and Silicone.PTFE is the most expensive

Silicone rubber: medical grade silicone rubber cost are huge difference :usually it is $6.25-$12.25 per kilogram for silicone rubber made in China. For some worldwide famous brands,such as “Dow Corning”,its Medical grade silicone unit price is around 40-50USD/KG. Silicone rubber takes up the most ratio in a silicone cable

Addictive:such as “color master batch””vulcanizing agent”

Factor 2

Cable Structure

No matter it is a silicone cable or other types cable,the More complicated the structure,the more defective rate and Process Loss will be

Factor 3

acceptance standard

In complex medical wire production, customer acceptance criteria directly impact final pricing:

- Compliance & Testing Costs: Higher standards often require additional testing and equipment, increasing costs by 10-15%.

- Quality Control & Scrap Rate: Stricter acceptance rates (e.g., 99% instead of 95%) raise scrap rates, impacting materials and labor costs by 1-3 times.

- Specialized Materials & Process Upgrades: Specific customer demands may require premium materials or line modifications, adding 20-30% to material costs.

- Pricing Model: Industry data suggests using a model:Final Price=Base Price+(Acceptance Complexity Coefficient×Production Cost)Final Price=Base Price+(Acceptance Complexity Coefficient×Production Cost)where this coefficient typically ranges from 1.1 to 1.3.

This data-driven approach helps transparently reflect the impact of acceptance criteria on pricing